A Comprehensive Guide: Repair or Replace A Crane?

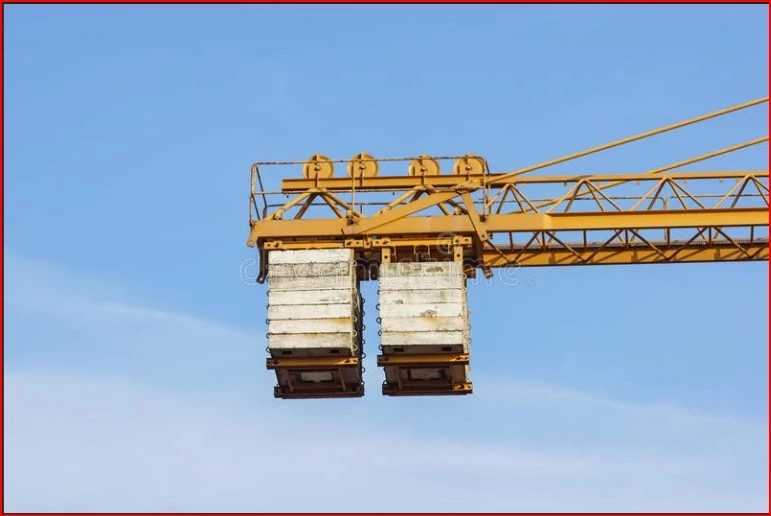

Your company needs tools that you can count on. It keeps things moving, keeps materials secure, and makes workers safer. Forklifts need to be level, and the overhead cranes need to be strong and stable enough to move big things. Crashes happen a lot with cranes, even though safety rules are in place to keep them safe. Cranes break down gradually, just like any other piece of machinery. As they do, they lose some of their usefulness.

While your overhead crane breaks down, repair or replace a crane. You can fix up your crane or get a new one. We'll examine the pros and cons of each option in the following article to assist you select the best choice for your business.

Why Repair?

It can be tempting to fix things as they go wrong because it's faster and costs less in the short term. But, based on what the problem is, these short-term savings could hurt your crane's long-term viability and make workers less secure in the long run.

When it's time to buy a new crane, these things happen:

-

Repairs over and over

Getting your crane fixed once in a while does not imply it's time to throw it away. However, if changes are happening all of the time or if every fix seems to make things worse, it may be time to swap out your crane or some of its key pieces.

-

Out-of-date guarantees

You can be pretty sure that an item or system is past its peak if its guarantee has run out. Additionally, many parts come with replacement dates suggested by the maker. Replacing old parts as soon as you can is the best thing to do.

-

Matters of safety

Don't put worker safety at risk. Keep track of how often injuries and breaks happen, particularly if you can't figure out what's causing them. If you're unsure if these problems are serious enough to warrant a repair, have an expert look at your crane and give you advice.

-

Getting less efficient

Check out your crane's success records. Has it become slower or less able to hold weight over time? Is it getting harder for your staff to run the crane? These modifications may not seem important at first, but they may have a big impact on how well and how much money your business makes.

Why Do You Need to Replace?

If your crane's structure is sturdy and there is no damage or wear, redoing it could make it last longer without affecting its security or usefulness. A complete replacement or repair may be all you require to cut down on problems, make the system more reliable, meet safety requirements, and keep your workers safe.

There are times when a crane that is otherwise in good shape may be an excellent choice for repair or rebuilding.

-

A certain method no longer works

Over time, each crane system breaks down. Systems that used to work well may not be able to meet the needs of current manufacturing either. If you update the lift, drive oversight, hydraulics, computer, or other parts of a crane that is otherwise in good shape, it could last for several additional years.

-

Safety measures are no longer as good as they used to be

There is a chance that the walks, steps, scaffolding, railings, and various other safety features will wear out before the crane does. By upgrading these features, you can keep using the crane whilst still meeting safety standards.

-

Not enough space

Newer technology has made it possible to adapt many older cranes for handling greater weights. In the past few decades, technology has made it possible for older cranes to carry less weight.

A few important things you can do to keep your crane in good shape

-

Checking the whole machine and all of its parts

Assuring safe use requires checking the crane's limits, trolley track, slide wire, entire power cable, and connections between the cart and the final beam and rails. For instance, examining the track bolts, how straight the track is, how worn the track is, and how much the rails are chewing helps keep the cart running smoothly.

-

Putting grease on cranes

Lubricating the crane properly is one of the most important parts of keeping it in good shape. When you use the gearbox for 200 hours or two months, you ought to change the oil that keeps it running smoothly. You should change the motor oil once a year after this first change. Gears are usually oiled centrally, and this must be done at regularly scheduled times for cranes. It's important to close the oil nozzle's sealed cap once adding oil to keep it from rusting.

-

A look at the machinery that makes the crane move

It is also essential to check the working parts of the cart as part of crane repair. Making sure the running process, gearbox, engine, brake, as well as brake space are all properly fixed is important for the crane's safe operation. It is very important to check the brake setting bolts as well as the nuts for tightness and change the friction layer if needed.

-

A look at the tram

To make sure the crane works safely, you must also check the mechanism for the trolley, the cushion fixing, as well as the mechanism for the trolley to move. Gearboxes as well as brakes should be checked for proper installation to maintain the crane moving smoothly.

-

A look inside the main electric box

Check the entryway of the wire into the control box, the transmitter for the remote control, as well as the condition of the terminal block ought to be part of the examination of the controlling electric box. Also, make sure that the wiring between all of the switches, contactors, as well as contacts is tight.

-

Checking the part that lifts

The most important part of crane repair is taking care of the part that lifts the load. To make sure that the reel, cable, hook, pulling limit switch, and various other parts work safely, check their surface wear as well as lubrication. It's also important to make sure that the tension block for the wire rope is tight as well as that the hooked head can turn easily.

Conclusion

So, now you must know, what is important: repair or replace A Crane? Get the best crane rental services and know more. Regular upkeep on cranes is important to make sure they work safely and cut down on delays for fixes. Maintaining cranes in good working order requires regular checks and lubrication, checking the whole vehicle as well as its parts, checking the crane's running mechanism, checking the controls electrical box, checking the trolley as well as checking the lifting part. By doing these things on a daily basis, crane operators can make sure that their machines last a long time and are safe.

- Tags:

- construction site safety