Crane Counterweight: What is it and Why is it Important

Cranes are very important construction tools as they are necessary both for lifting and carrying heavy objects and also for doing various types of works. Frequently, the counterweight, which is the basic part of machine operation, is forgotten. This is important as it affects the efficiency and security of this large-scale machine. In this blog post, we'll look at the Crane Counterweight: What, when, who, and how. Get a cup of hot tea and join the crusade as we evaluate the different systems of counterweights, focal elements, and the benefits of using mobile cranes.

What is the Counterweights' Function in Crane Operations

As regards the crane activities, a counterweight is a weight placed diagonally from the pivoting point of the crane which offers a balance and stability while hoisting. Typically, this mass is made of cement or steel. With their ability to maintain stability and prevent the crane from toppling over under the weight of enormous loads, such counterweights are an integral aspect of a crane's construction.

Types of Cranes and Their Counterweight Mechanisms

-

Transportable Cranes:

Mobile cranes, such as trucks, crawlers, as well as terrain cranes, primarily use counterweights to maintain the equilibrium of the load being raised and steady the machine. Typically located at the back of the crane, counterweights are movable to accommodate different lifting capacities. Sometimes, mobile cranes will use a combination of movable as well as permanent counterweights to achieve the right balance for a particular lift.

-

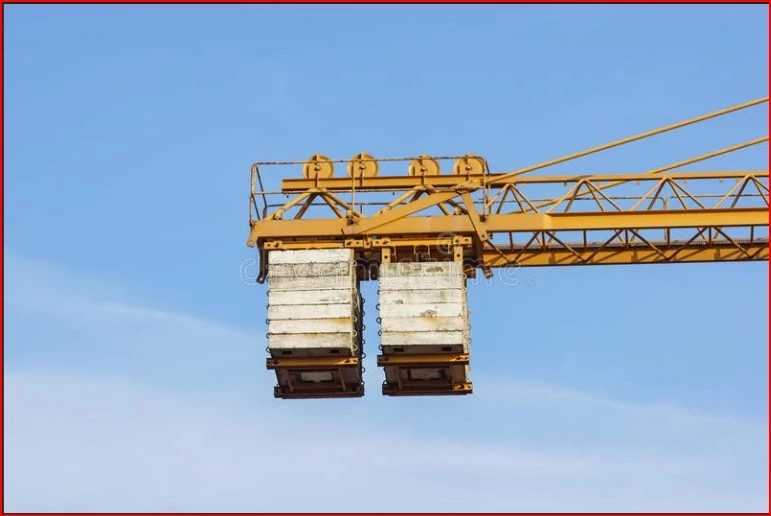

Tower Cranes:

Construction sites are frequent places to see tower cranes. It is made up of a main beam called the mast, a wide sail called a jib that puts its strength against the force from the wind, and a counter-jib which holds the weight for balance. They keep the crane centered and level during lifting. Both counterweights are located at the other set of the jib. Observing the amount of weight to be suspended and the distance the jib can reach, one must determine the quantity and size of weights to guarantee maximum safety and performance.

Operation of Counterweights

The counterweights of cranes are usually mounted near the main support behind the arm or jib of the crane. The purpose of this configuration is for the provision of steady support when lifting the material.

The Role of Dynamic Stability for Cranes

They are responsible for the crane’s horizontal balance and stability as cranes transport massive loads. Counterweights mitigate vibration and stress from the higher load during functioning, hence promoting a stable and secure working environment. The fact that counterweights improve the lifting capacity and effectiveness of cranes is another significant benefit. They make it possible for cranes to operate at their peak capacity by enabling them to lift heavy loads and ascend higher.

What do the tower crane's counterweights do?

For counterweights to have the most efficiency with minimum weight, they need to have the right mass and distance from the center of gravity. We will name this, as a trigonometric point, which is equal to the mass of the counterweight multiplied by its distance from the pivot. Counterweights also play a crucial role in times of lifting and storage of weights. For optimal performance, the counterbalance moment must match the load moment. It's crucial because the dominating side will fall if one side has a bigger moment than the other.

In a tower crane setup, what is the function of a counterweight?

Counterweights for cranes are also essential for worker safety in the construction area. In order to prevent the crane from toppling over, there is a counterbalance. Get a cup of hot coffee and know how the object being raised has its weight counterbalanced by the counterweight. The majority of the time, the weights help cranes dig holes or lift large objects.

Counterweights move slowly, yet it's still important to use caution when using them. Ensure the crane operator is aware of your presence if you are passing the counterweight to avoid becoming caught between it and other nearby immovable objects.

You could be pinched among the two locations and suffer severe injuries, if not die. Position of the balancing wheel is critical. Under proper building, extent, and design, this topic can be a hurdle and can cause the vehicle to roll forward or backward with the load being carried.

A crane will fall in the direction of the load if its counterweight arrangement becomes too weak to bear the load and dash up the system.

The counterbalance as a boom set-up is extremely high. The crane is jamming in an incline. While handling on soft soil the crane has the inadequate pile of timber under the outrigged pads that are below the counterweight. Because the outriggers are not lowered or put down, they end up not being able to withstand all of these weights as well as the side pressure of the toppling process. For instance, if the zoom is not done correctly then its design would elevate too high.

Correct Counterweight Calculation

Firstly, if the formulas and calculations are done incorrectly, the crane might tip over. Thus, the weight and dimension are important to measure during the design step which should be accomplished prior to real manufacturing. There is absolutely no alternative for the successful handling of the crane counterweight.

Utilize the following mathematical equation when building the part to lower potential dangers and offer an effective counterbalance: P=gVμx. Weight (P) serves as the counterweight; volume (V); density (μ) means the material's density; also gravitational constant (g) takes the value of 9. 81).

Conclusion

Crane counterweights assure safe operation by keeping the car steady. This helps with safe operation of the machine. Apart from the best methods of construction, the most durable raw material range—grey wrought iron—and periodical security checks are the necessary preconditions for the efficient performance of high-quality clappers.