Top Tips for Heavy Equipment Maintenance

Heavy equipment maintenance is not an easy task. You must know how to use it properly. Here are some top tips for effectively maintaining your heavy equipment:

-

Follow Manufacturer Guidelines:

You must go through all the guidelines and read at least once. Observing these guidelines is important in preparing to maintain your machinery in as perfect a state as possible. It also entails suggested service intervals, lubrication points, and inspection checkpoints. However, it is also wise to ensure that the operators have knowledge of the manual and are compliant with the guides strictly.

-

Regular Inspections:

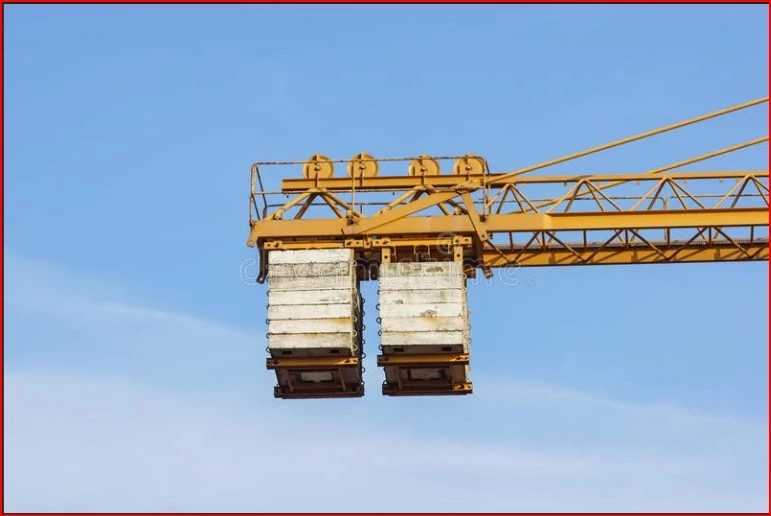

Performing on-the-scene check-ups of facilities before and after their use can help avoid considerable problems. As for maintenance, you should check the activity and durability status of the product by observing corrosion, loose threads, fluid drips or loss, and flawed parts. Particularly focus on potential fatal aspects of the vehicle, namely hydraulic system, brakes, tires, optimal electrical connections, and others. If these issues are not noticed and dealt with when they are easily manageable, then they are likely to grow into issues that can cause operations to come to a standstill. Grab a cup of tea and then you must think: Replace or rent a crane? You must rent it.

-

Keep it Clean:

Cleaning should be done with pressure washers, brushes, and degreasers to ensure that all equipment is properly clean with close to impossible-to-reach areas. Although it is crucial in aesthetics to maintain the proper outer surface of machinery or its tools, there are other benefits which result with regular cleaning, such as reducing chances of experiencing corrosion or mechanical faults.

-

Monitor Fluid Levels:

Note that different types of fluids are important for the effective working of heavy equipment and that correct levels of these fluids must be maintained. Sufficient fluids cause the engine to heat up; some components get damaged or even cause a breakdown if it gets low. In Scissor cranes, it is easy to balance fluid level. Know how to take scissor lift on rent.

-

Lubricate Moving Parts:

Many parts are movable in heavy equipment, and to minimize friction as well as wear, lubrication is paramount in such equipment. Adhere strictly to the manufacturer's recommended time intervals for lubrication, and where applicable, always use the right lubricants for the specific part. The grease fittings and bearings, chains and pivot points should be regularly doused with lubrication to enhance their durability and proper functioning. It also helps to prevent rust and corrosion of the equipment as a result of activities such as regular greasing.

-

Replace Filters Regularly:

Filters are an important unit in the process of preserving the purity of fluids and air consumed by heavy machines. Maintenance on engines should include periodic inspection and replacement of the engine air filters, fuel filters, hydraulic filters, and transmission filters as recommended by the manufacturer. Unclean or blocked filters may also affect the airflow and the efficiency and reliability of the engine, and even lead to negative effects on the performance of the car. It also put the filter on a regular replacement schedule to avoid contamination and ensure efficiency of the gadget.

-

Check Electrical Systems:

Electric parts are essential in the functioning of most sophisticated devices found on today’s heavy equipment. Another preventative measure involves checking for signs of wire damage, connectors, and batteries periodically. It is required to check all the lighting, gauges and other control safety features to make sure that all the electrical units are working ok. Schedule a service call as soon as you notice any problem as far as wiring or electrical components are concerned to avoid breakdowns and risks.

-

Inspect Undercarriage Components:

Other tracked vehicles and equipment like bulldozers, excavators and the like tend to depend on its undercarriage to offer it rigidity and grip. The other common checks that should be carried out frequently include track and running gear check consisting of track links and support rollers, idlers, and sprockets. If any parts appear to be frayed or worn out, it is best to replace them immediately to avert costly repairs on the machinery as well as the pull of having to wait for several days for other parts to be prepared. In undercarriage maintenance, it is important to prevent the premature wear of tracks and ensure the machines provide optimal performance.

-

Train Operators Properly:

Training of the equipment operators is crucial in the prevention of exposing the bulky tools to a lot of use and thus reduces the chances of developing several complications. You should hire trained and certified machine operators. All operators should be instructed in correct procedures in starting up/stopping and operating, techniques in handling and operating the gears and handling the machines or equipment. Emphasize the fact that operators should seek assistance if they notice anything strange or if the machines make any funny noises. By acquiring training and experience in their work, the operators know special signs that are indicative of more severe damage and thus prevent additional maintenance problems.

-

Schedule Preventive Maintenance:

Grab a cup of coffee and prepare with a schedule for regular servicing and checkup to ensure that all parts of the car are in proper functioning to avoid hasty service. To ensure that all those tasks are done appropriately, you should be able to come up with a schedule of maintenance and schedule check list with their respective intervals and strictly follow them. Guaranteeing Your Services – Utilise maintenance management software to ensure service history, set up reminders and produce reports in order to enhance the coverage and quality of various services. It means that in this case potential failures are eliminated prior to their development and become less critical, which necessitates less frequent and less expensive repairs.

Conclusion

Therefore, constituting the provision of efficient and adequate maintenance of heavy equipment as an integral activity in its use is crucial. You should also know more about crane rental services. Suppose you adhere to these general guidelines on your site. In that case, the efficiency of operation of some machinery will be extended, losses of working times will be corrected, and handling of your machinery will be safe. It is therefore important to ensure that the HE gets inspected regularly, adequately lubricated, its fluids well maintained and the operators well trained to enhance the maximum utilization of these resources. This helps to ensure that the reliability of your equipment is maintained for a long time to help improve the productivity of the production floor.