Scope of Rental Crane Technology

We have seen AI making many changes in daily life and business processing. Crane and aerial machines have also witnessed a significant overhaul in terms of technology. They are now equipped to do more than just lifting. They access aerial operations and even alert them of any hazard. New technology brings a new scope of work.

Many heavy-weight lifting technologies have made construction sites safe to work on. Some technologies are already in India, while we may see some in the coming years. Let us look at how rental crane technology can make a difference in construction and industrial setups.

Top Crane Technologies to Look Out For

1- Aerial survey technology:

Drones have made it easy to inspect elevated and hard-to-reach spaces, and their introduction in the aerial assessment has been of great appreciation. The drones are being used to check the structural integrity of the working cranes. The areas where aerial survival technology is being used are the oil and gas sectors. Rigging cranes, in particular, are the most dangerous to access, but these flying bodies with cameras help inspectors ensure safety with proper virtual evaluation.

In the future, we can expect drones to provide high-definition photographs and computer analysis of crane defects. We may, however, still need a traditional method of crane inspection, but drones certainly help crane operators ensure safety on the project site.

2- Simulator For Training:

In the coming years, we may see a complete overhaul of how operators are trained. A new technology that uses a stimulator is being tested to help train operators through virtual training. The training will significantly reduce the cost of preparing an operator. The operator in training will learn how to safely carry out the operations without danger to anyone on the project site.

The simulator will record all trainee activity, including the time taken to complete the training, the number of collisions during the stimulator training, and how smoothly the operator performed. The simulator will also provide feedback to the trainer on whether or not an operator is fit for the job.

3 - Remote Load Management System:

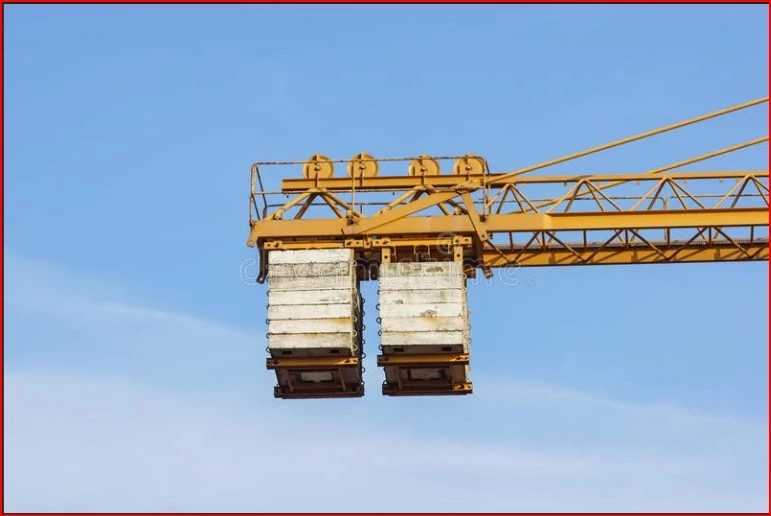

A new safety system called R-series for load management has already been deployed. Some cranes are using the technology to eliminate the need for human-held taglines to control suspended loads. This helps enhance safety and productivity on the project site.

The technology allows the operators to control the load from inside the crane. Less human power is needed to direct the load lifting and downloading. Depending on the model variant, the R-series technology can handle a load of 20-400 tones. All R-series models are connected with smart software, which helps calculate real-time load movement.

4 - Manitowoc’s Configurator:

Manitowoc Cranes has introduced a new app for Android and iOS that lets the operator and crane owner calculate the jib and boom length required to complete lifting tasks. The app lets the users add site information such as structure heights, boom radii, and other parameters to calculate the basic crane setup required for the lifting task.

The requirement for cranes has increased in India amid a rise in the number of construction projects. Post-pandemic, many new construction projects have been initiated to support industrial development on an international scale. Using a crane with high technology can help operators and project managers easily complete difficult tasks.

If you are looking for a technology that makes construction projects easier and more rewarding, contact Sky Manlift today. Sky Manlift provides various aerial lift solutions, including scissor lifts, boom lifts, man lifts, cherry pickers, and more.

- Tags: