Tower Cranes: Types and Where to Use

There are several widely used cranes for construction work, especially within the cities. Such tall and huge cranes are useful in transporting and lifting very heavy weights like machinery, steel frames and c concrete blocks. However, every single type of tower crane can always be used for the best work. Several types of work are great for several types of cranes. Our blog will help you to learn about the best ideas about the tower cranes and their importance in several construction sectors, as well as the best types of tower cranes and their utilizations.

What is a Tower Crane?

A tower crane one of the best slews or equipment utilized for lowering, lifting, and hoisting of the best materials in a vertical as well as horizontal manner. It is usually supported by a concrete slab floor, with three tall legs and one long horizontal extension called the jib (or boom), which aids in transporting materials across a large span. A tower crane is capable of toiling some of the heaviest loads ever and is needed for the construction of tall structures such as skyscrapers, bridges, and big infrastructure projects. Want to rent cranes? Know more about crane rental services.

Types of Tower Cranes

Tower cranes of different types are useful for various operations depending on their structure and construction. The main types include:

1. Hammerhead Cranes

2. Luffing Jib Cranes

3. Self-Uplifting Cranes

-

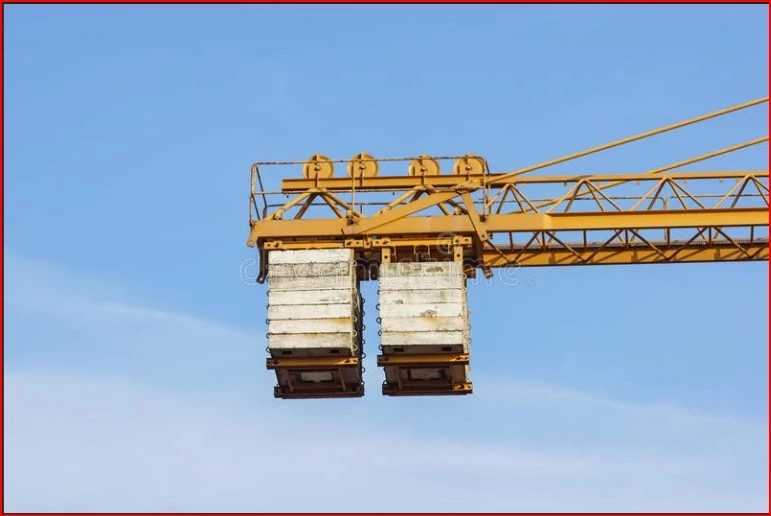

Hammerhead Cranes

Tower cranes are large and can be of various types, with hammerhead cranes being the most popular. They have only a fixed horizontal jib that can revolve around a rotating mast which is vertical. This trolley also travels down the jib in a bid to ferry materials.

Features:

-

Jib: Jib type is fixed in the horizontal position.

-

Movement: Trolleys roam from one end of jib to another in a to and fro motion.

-

Rotation: Full rotation around the mast, obtaining a 360-degree view of the surrounding area.

Uses:

-

Suitable for general construction processes.

-

Being applied majorly in the construction of high rises such as apartment buildings, business endeavors, and other related enterprises.

-

Ideal for areas where there is adequate room to maneuver the jib into different positions and angles.

-

Luffing Jib Cranes

Compared to the hammerhead cranes, whose horizontal jib is fixed, the luffing jib cranes have a jib that can be tilted upwards or lowered downwards. This makes them very flexible for use, particularly in congested regions such as construction sites. Read the best blogs on construction equipment to know more about it.

Features:

-

Jib: Can be raised or lowered, thus also called the ‘luff.’

-

Movement: These include movements which involve oscillating the jib up and down.

-

Rotation: The first and foremost is the full 360-degree rotation around the mast.

Uses:

-

Ideal for construction sites in metropolitan areas where the construction area is constrained.

-

Perfect for the construction of structures in congested areas where there cannot be much swinging of the jib.

-

Usually employed on slim, tall structures, for instance, the high-rising structures.

-

Self-Uplifting Cranes

Self-uplifting cranes have been very portable in collapsible. It also helps to make them very easy to uplift and transport. Such types of cranes are very light and more easily accessible from very low to high-rise construction work. Do you want to rent a crane? Check out the crane rental services.

Features:

-

Jib: It is a horizontal arm extending from a portal or an enclosed frame.

-

Movement: Trolley travels on the jib, as in hammerhead cranes.

-

Setup: Easily transportable and does not have to be erected or dismantled with a big team or more cranes.

Uses:

-

Primarily used for small construction projects, for instance, building houses or small business premises.

-

Best suited for short-term application if the locations are easy to mobilize and demobilize.

-

Work well with areas where cranes can hardly be positioned.

How to Select the correct tower crane

Several factors must be considered while deciding on which tower crane to use: the height of the construction, the weight of the building materials, the available working area, and the time needed for construction.

-

Height: Special types of cranes, like the hammerhead cranes, are used for very tall structures because they can support the loads well.

-

Space: Luffing jib cranes are especially well-suited for use in densely populated metropolitan areas because their booms can be maneuvered around structures.

-

Project Duration: These cranes can be self-erecting, and they are easy to set up and dismantle especially for short-term projects.

-

Load Capacity: Depending on the application and the amount of weight that has to be lifted and moved, hammerhead cranes are usually preferred because of their ability to lift more than other types.

Safety Considerations

The main goal while operating the tower cranes is to avoid any accidents and have a successful completion of the construction process.

-

Regular Maintenance

Regular checks It is also crucial to note that maintenance of tower cranes must be used in a great way where you want to avoid a mechanical breakdown that is a potential reason of the accident. Also, know more about construction equipment.

Maintenance schedules should involve inspection of the structural rigidity of the crane. It confirms that all bolts and connecting points are rightly fixed. Also, it has a confirmation of the efficiency of the lubricating system and the overall functioning of the moving parts. In general, it is essential to focus on maintenance that allows for early detection of problems that may lead to serious, adverse effects on the functionality and safety of the crane.

-

Qualified Operators

It is also important to ensure that only qualified and certified people operate tower cranes. Some factors need to be observed when operating a tower crane, such as the control mechanism of the crane and its ability to handle loads, among others. Certified operators understand various aspects like load management operation of the crane within tight spaces and in case of an emergency. The use of operators lowers the risk associated with the crane and ensures that the crane is operated as it is prescribed.

-

Weather Conditions

This is true because working environments can greatly affect the safety of a tower crane. Operators should keep abreast of the weather conditions. It makes crane operations dangerous, and refrain from operating the cranes within such weather conditions, including strong winds, heavy rainfall and thunderstorms. Another aspect of ensuring safety of operations conducted with a crane is securing the crane and any other load. It may be hanging from the crane when it is not actively being used to avoid accidents resulting from changes in the weather.

Conclusion

Modern constructions cannot work without tower cranes, which are the devices that are responsible for the construction of high-rise buildings and large infrastructural structures. Familiarisation with the various tower cranes and their applications is significant in selecting the appropriate equipment for a project. It also promotes the achievement of high goals of efficiency, safety, and success within the project. Also, it is beneficial to know the role of cranes in medical facility construction. From the hammerhead crane with its multi-purpose capabilities to the luffing jib crane, it occupies little space. Also, the self-erecting crane with its instant assembly, has a part to play in the construction of our cities.